01. CCS (Cells Contact System) is mainly composed of signal acquisition components (FPC, PCB, FFC, etc.), plastic structural components, copper aluminum busbars, etc., which are integrated through processes such as hot pressing or riveting to achieve high-voltage series parallel connection of battery cells and the temperature and cell voltage

02. CCS provide temperature and voltage data to the BMS system through FPC/PCB and connector components, it is a part of the BMS system

01-Introduction of the CCS/Cells Contact System

Ø CCS (Cells Contact System) is mainly composed of signal acquisition components (FPC, PCB, FFC, etc.), plastic structural components, copper aluminum busbars, etc., which are integrated through processes such as hot pressing or riveting to achieve high-voltage series parallel connection of battery cells and the temperature and cell voltage signal acquisition of the battery pack

Ø CCS provide temperature and voltage data to the BMS system through FPC/PCB and connector components, it is a part of the BMS system

Ø CCS with FPC as signal acquisition components with the advantages of high integrationhas, lightweight and compact structure.It will improve the space utilization and assembly efficiency of battery packs, which is in line with the trend of automotive lightweighting, component system integration, and large module assembly

02-The Hot Pressing Process of the CCS/Cells Contact System

Ø The CCS hot pressing process uses PET insulation film to instead isolation plates to compress aluminum busbars and signal acquisition components into thin sheets to achieve a reduction in product volume, weight, and accessory quantity

Ø This process makes the CCS integrated busbar structure more thinner, more organized and high integration, reliable sealing and insulation, and can be automatically assembled to improve the space utilization and production efficiency of battery modules. It is in line with the industry development trend and has developed rapidly in recent years

03-The Market Demand of the CCS/Cells Contact System

Ø With the rapid transformation of the automotive industry towards electrification, intelligence, and lightweight, the development of the new energy vehicle market is very promising

Ø As one of the core components of new energy vehicles, the quality of new energy batteries determines the performance of the entire vehicle. New energy batteries are generally composed of multiple battery modules, each equipped with a set of CCS

04-The Advantages of the CCS/Cells Contact System

Ø Integrated hot pressing,which with good circuit sealing, good moisture resistance, good oxidation resistance, good corrosion resistance, etc., excellent performance and high reliability

Ø The client side installation is simple, avoiding the tedious process of connecting too many wire harnesses, and has a high degree of automation, saving customers' assembly labor costs

Ø High integration, small size, lightweight, saving overall module space, making the overall module lightweight and convenient

Ø Strong universality, strong manufacturability, easy modularization and standardization, saving development costs

Ø The circuit is designed with overcurrent protection to protect the battery cells, ensuring high safety performance

Ø The connection method with the battery cell is flexible, allowing for multiple series and parallel connections, and has a wide range of applicability

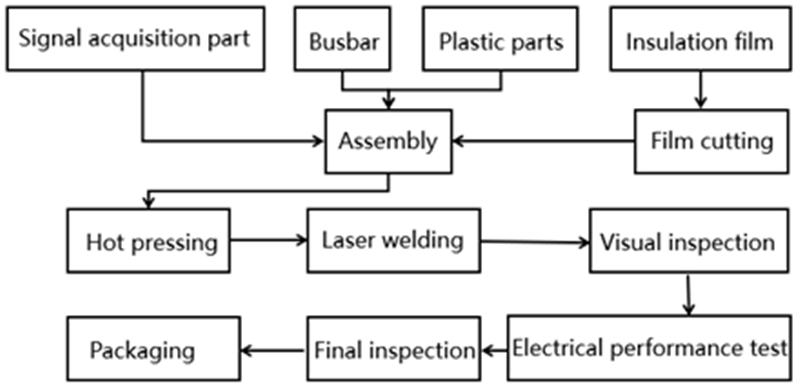

05-The Manufacturing Process Chart of the CCS/Cells Contact System