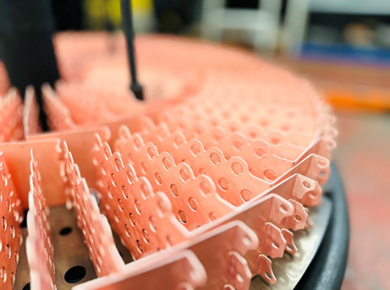

REDDITCH, England-Engineers at Samuel Taylor Ltd. We have developed a new aluminium-to-copper bonding process that is ideal for electric vehicle battery applications, such as bus bars.

“Our bonding technique overcomes the challenge of aluminium’s high reactivity to oxygen, making it very difficult to bond” says Alastair Gordon, managing director of STL. “Achieving this has enabled [us] to create a proprietary cold-cladding process that we can now use to produce aluminium-copper bimetal strip.

It is well suited to many different applications, offering significant future potential for further EV applications beyond connectors,” claims Gordon. “We have a proven record in innovation, such as our recent work to develop a new production process to enable the production of over 70,000 bus bars for the battery packs of the world’s first fully electric British hypercar….”

KEYWORDS: Aluminum joining/ Aluminum parts/ Battery assembly Battery manufacturing/Copper/ Electric vehicle battery/ Electric vehicles/Electrical connectors,Copper Foil Flexible Busbar,Aluminium Foil Flexible Busbar,Copper Braided Wire Flexible Busbar,Rigid Cu/Al Busbar,Cu-Al Composite Busbar,CCS/Cells Contact System/Integrated Busbar),Lamilated Busbar,Low Presssure Injection Busbar,CNC Precision metal parts.